While i was constructing the staging yard module it occurred to me that it would be handy to also build a master alignment module. Others who were building similar modules could then carry home with them and align their module end track to this master alignment module . This would then ensure that all the modules and their end track pieces would align with each other …..

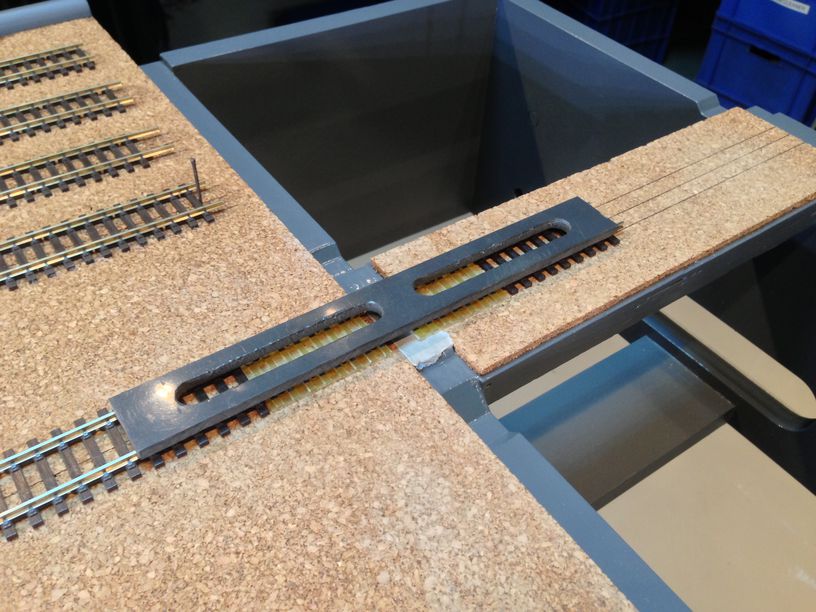

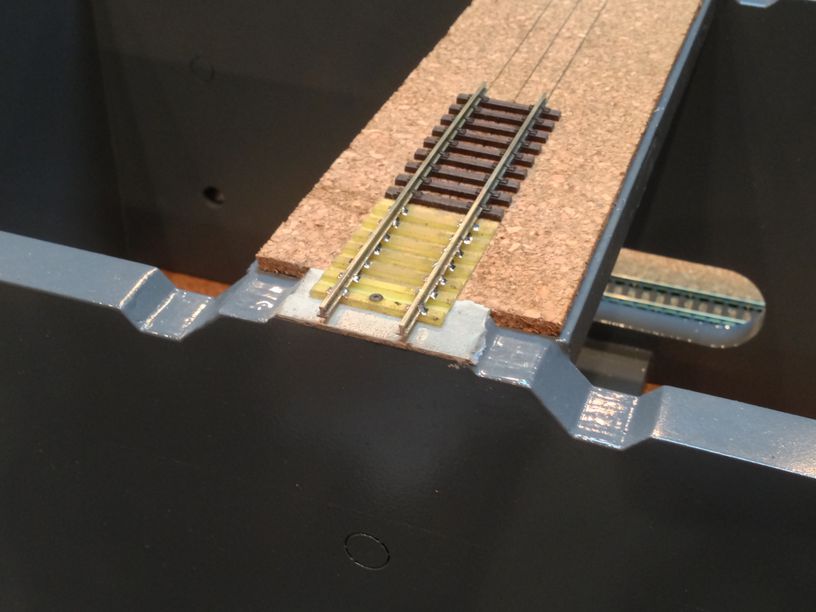

To this end i had constructed a small mini module , about 250 mm in length and using two Fremo 500mm end faceplates …..

I then attached it to the end of the staging yard module ……

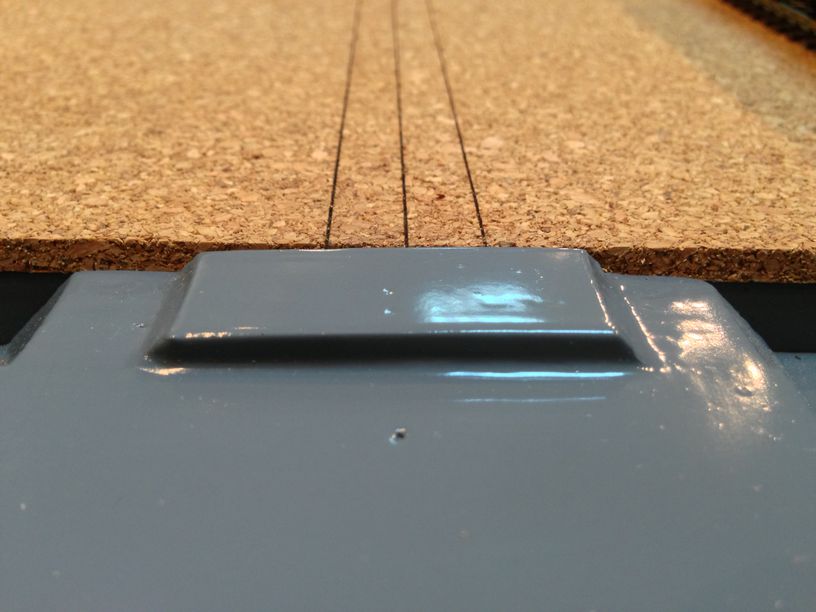

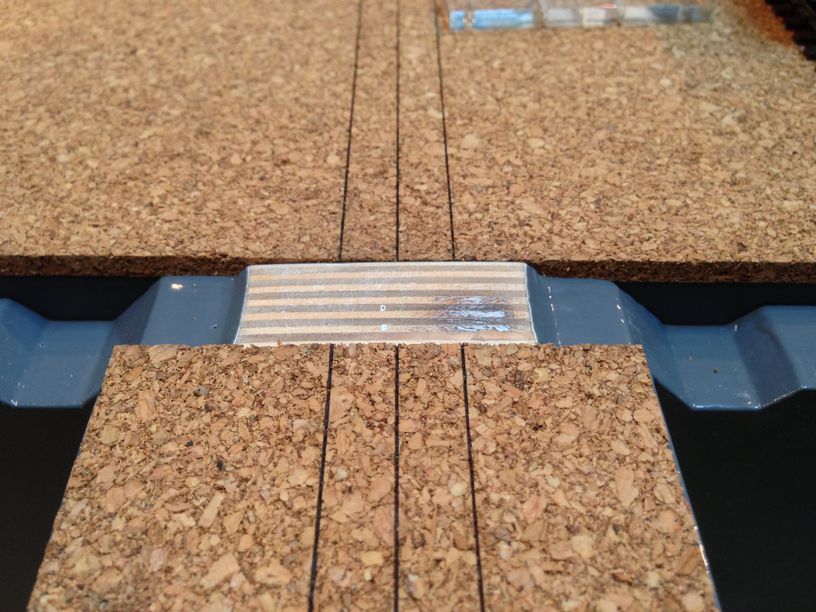

and noticed a slight defect in the module end which prevented it from aligning perfectly in height . This defect was probably brought about by excessive sanding during the painting process …..

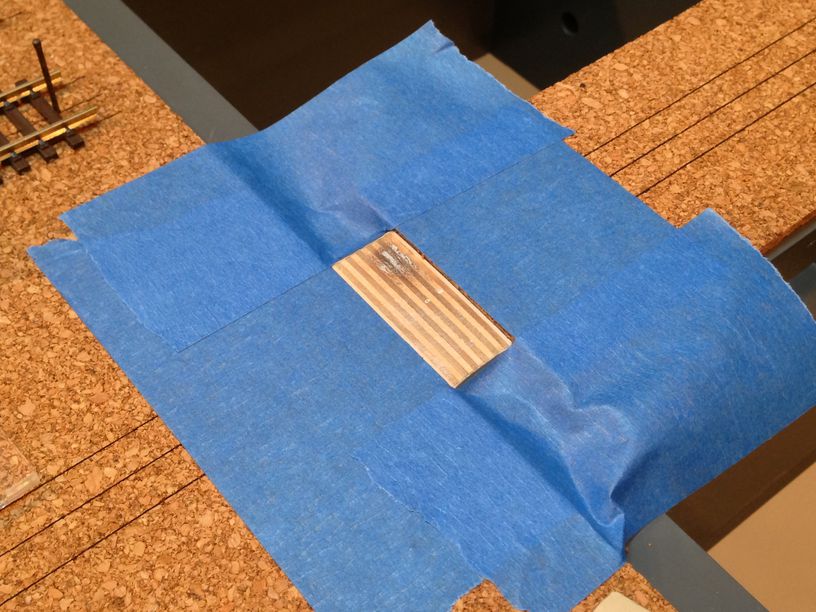

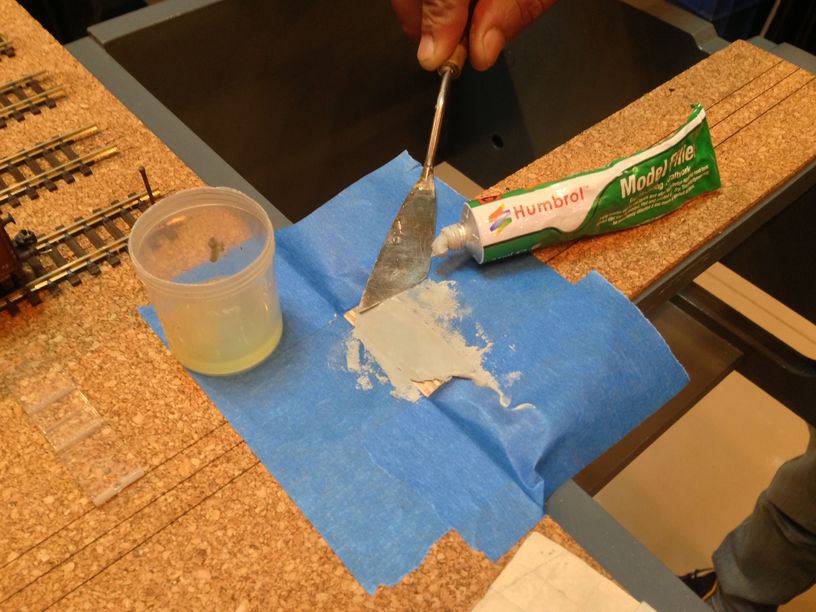

anyhow , i added the cork roadbed, sanded the paint off and after masking the area around the crest , leveled it up with humbrol filler…..

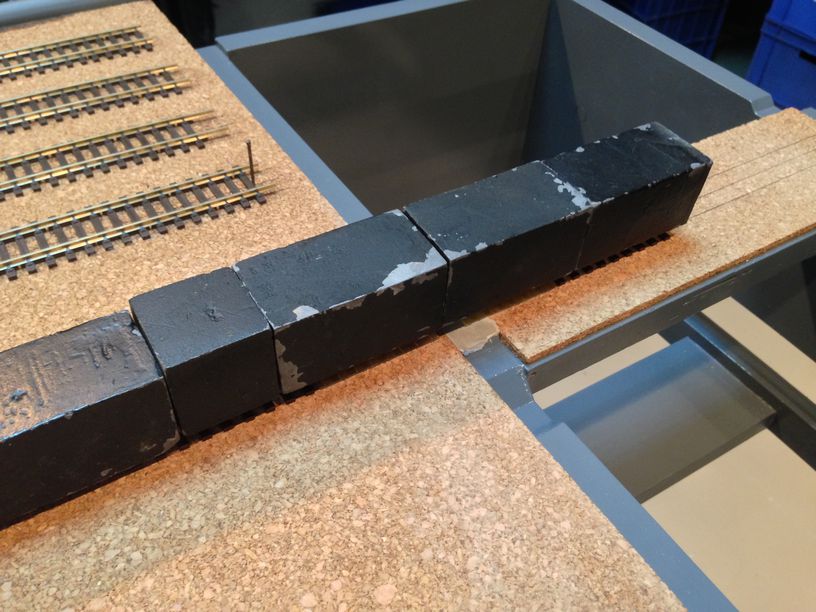

i then proceeded to sand down and level the alignment module, the humbrol filler and the staging yard module in one fell swoop……….

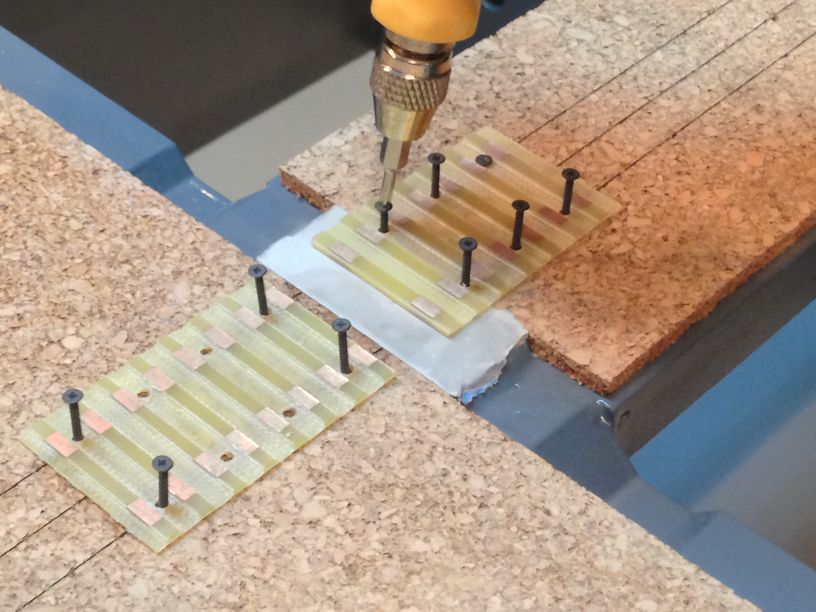

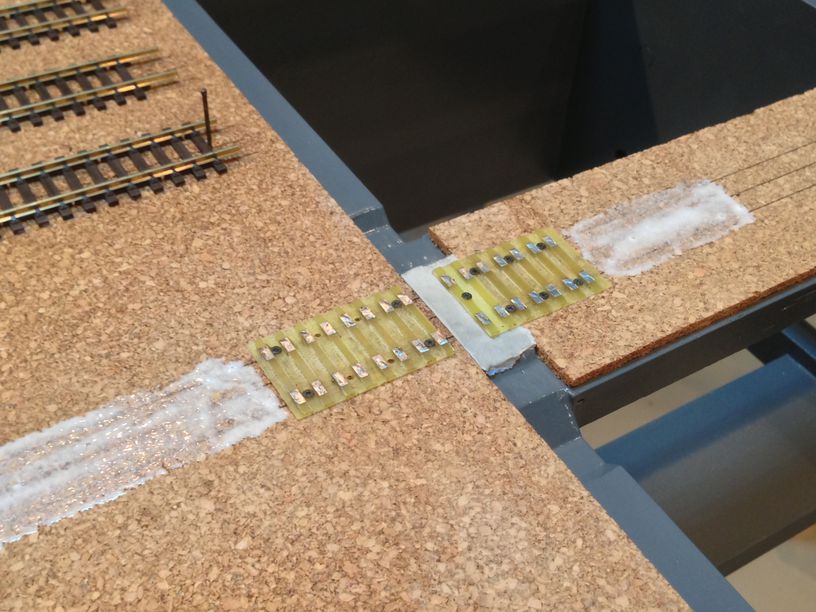

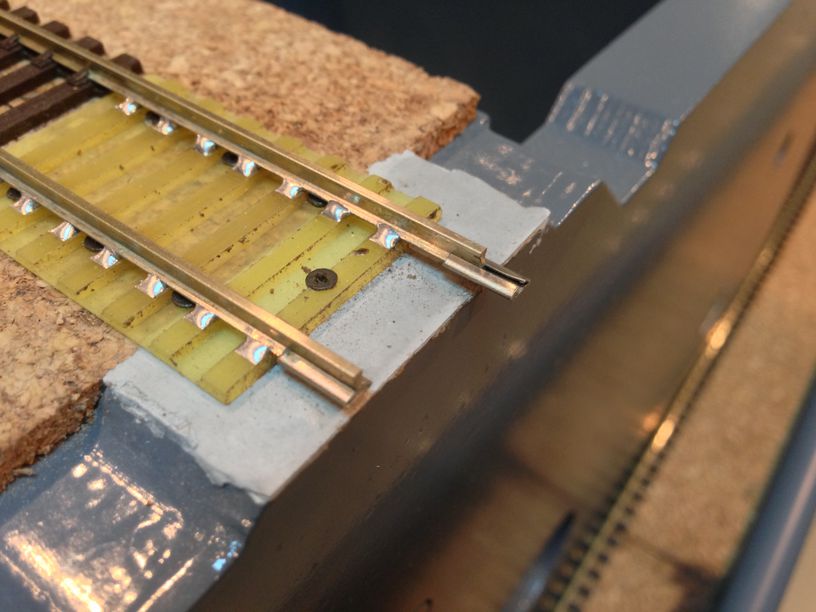

i then proceeded to add the tie plates using the install jig , lining it up with the engraved track and center lines in the cork ……

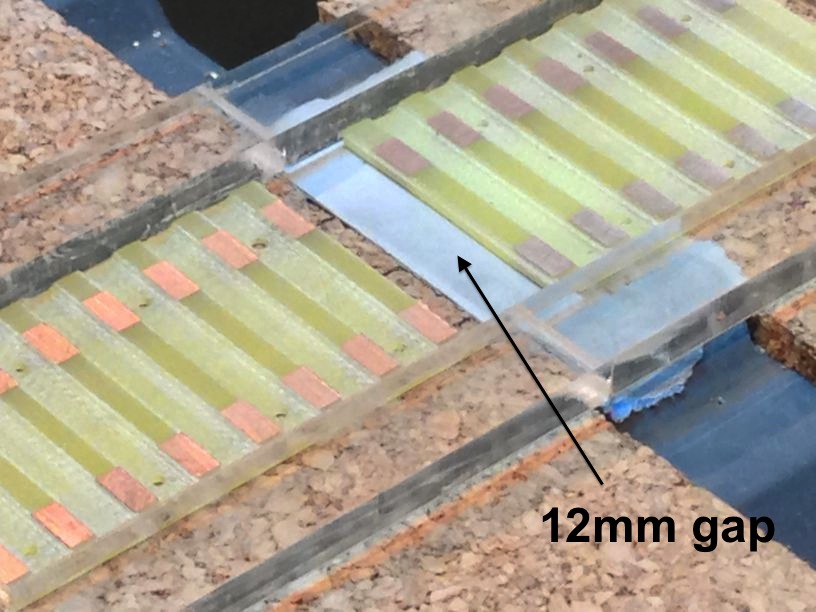

this time i had cut off one of the tie plates with a gap of around 12 mm from the edge ……. later on when the track is installed and cut , i can slip in rail joiners into the gap which in turn will allow better alignment with the adjacent modules

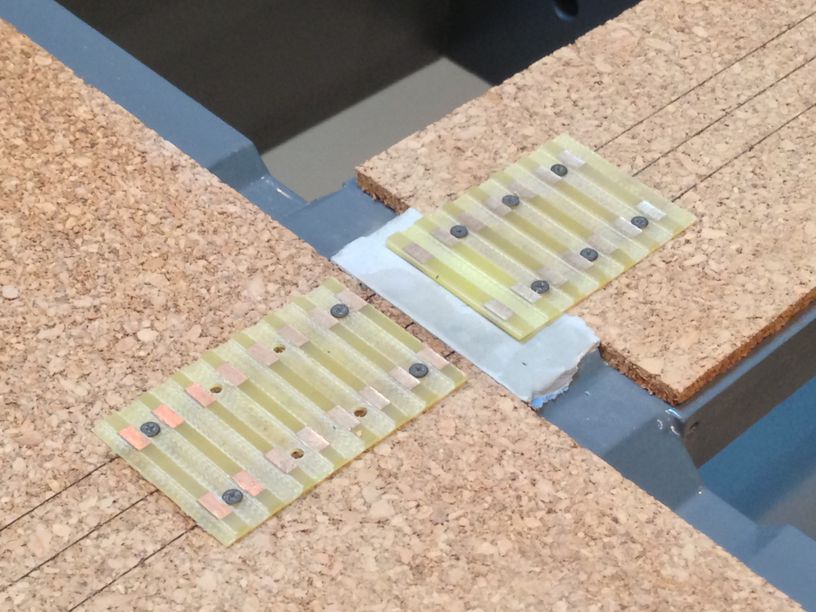

once the glue dried i drilled in the holes and put in the screws …….

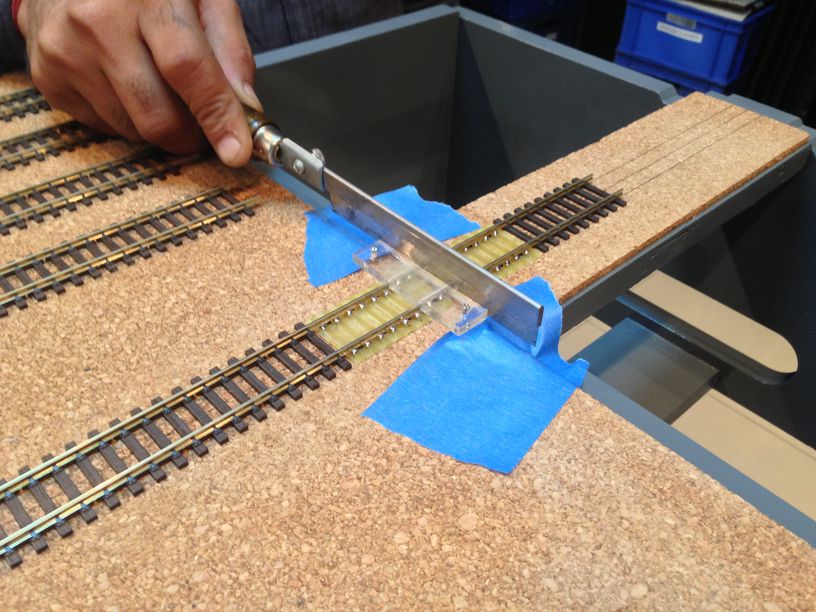

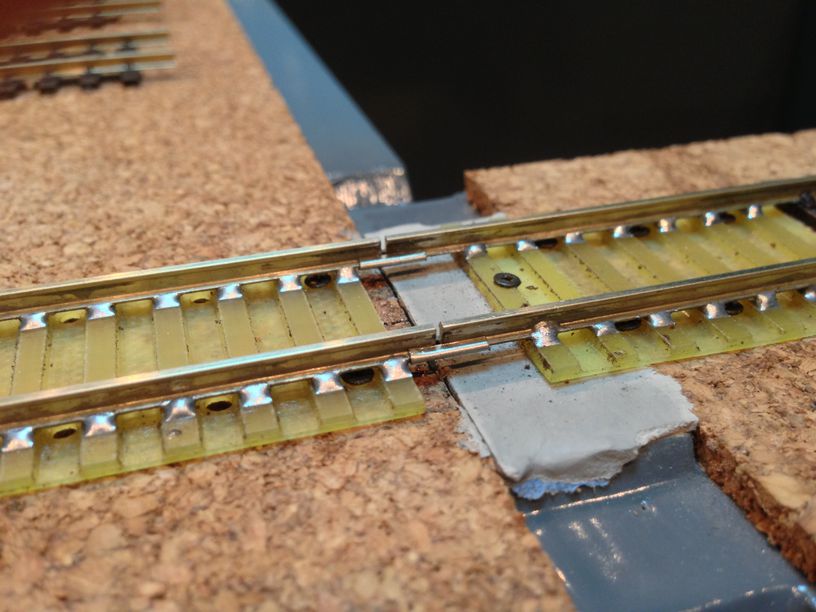

i then test fitted the track section and aligned it using a jig which would help keep it straight, i glued and weighted down the track….

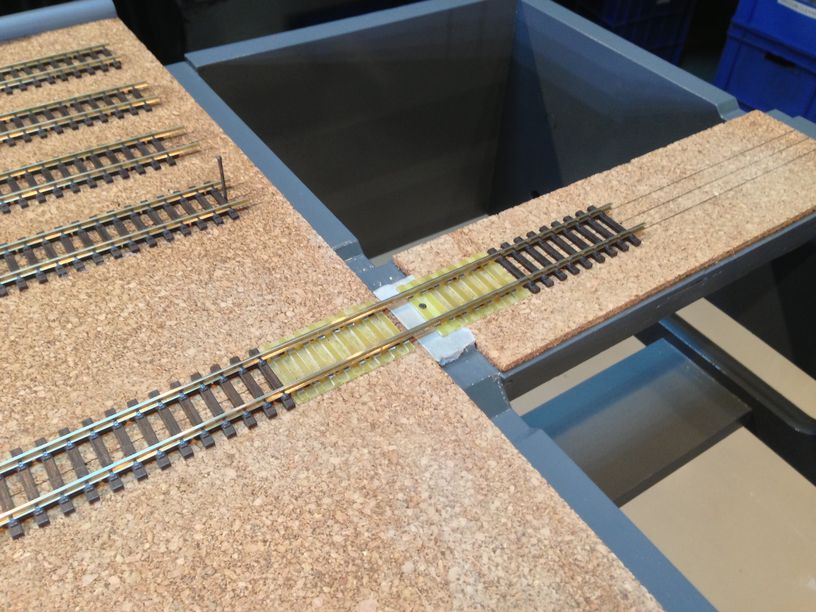

once the glue setup i cut the track with a Zona saw and separated the module ….

in the 12mm gap i had left at the modules edge , i was able to insert half cut rail joiners …..

which will help track on other modules to align both horizontally and vertically ……..

here is the finished product …. a mini module in its own right ………

hi doug

the etched end pieces were bought from BNM hobbies

the link is – http://www.bnm-hobbies.com/store/index.php?main_page=product_info&cPath=20_21&products_id=211

also have a look at this post for a more detailed installation of these etched end pieces – http://vikaschander.com/fremo-modular-layout/track-across-modules/

cheers

vikas

Hey Vikus

thank you for the detailed way in which you have done the track ends. I have seen the completed ends in many different searches that I have done in google. How ever I would like to ask how you etched the end pieces prior to soldering the track

regards

Doug

This is an excellent idea as it allows the whole group to get to the same standard without hauling modules to each others houses… Thank you for the effort.